FOUNDRY

THERMAL

THERMAL

$380.00

FAQ: https://r.works/thermal-faq

NOTE: This is a PREORDER. Shipping will commence when manufacturing/assembly has completed. Follow https://rama.works/updates for the latest updates.

SWITCHES, STABILISERS AND KEYCAPS ARE NOT INCLUDED!

Switches/Stabilisers are offered in the THERMAL Starter Kit

Plates [Extra]: https://ramaworks.store/products/thermal-plate-extra

The BEAM plate is already included with each THERMAL.

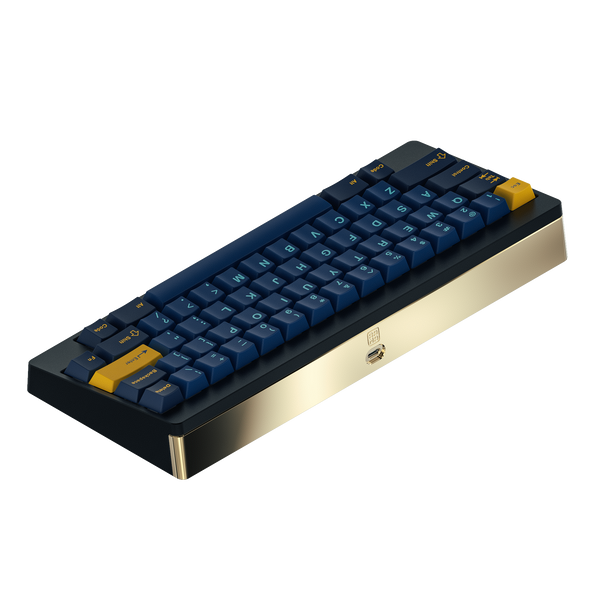

Thermal is a convergence of extremes, evoking the past while being contemporary, building on experience while experimenting with new ideas.

Its brutally sharp aesthetics are audacious, yet refined. Innovative engineering transforms the hardness of metal into a soft and vibrant typing experience.

From the interior to the exterior, each element is meticulously designed and expertly crafted for optimal performance.

Case and PCB design by wilba.tech

Manufactured and distributed by RAMA WORKS® FOUNDRY

Product Color Options:

KURO (Black) with BEAM plate (polished aluminium)

HALT (Red) with BEAM plate (polished aluminium)

MIST (Silver) with BEAM plate (polished aluminium)

MOON (Grey) with BEAM plate (polished aluminium)

Case Top Options:

HHKB - 1.5U corner blockers, for the HHKB layout using 7U spacebar.

FULL - no blockers, for a full 60% layout using 7U spacebar.

Note: 2U Backspace and stepped caps lock support only with WT60-BX PCB (solderable).

PCB Options:

The WT60-B PCB uses Kailh hotswap sockets for assembly without soldering.

The WT60-Bx PCB is the solderable variant and provides full 2U backspace and stepped caps lock support.

Finish:

Beadblasted Anodized Aircraft-Grade Aluminium Body & Polished Anodized Aircraft-Grade Aluminium Plate

Interface:

USB-C

Weight (built - estimate):

1500g

Case Slope Angle:

8.0°

Features:

Leaf Spring Mount, 1.5mm Aluminium Plate with 8 x 90mm x 1.5mm x 1.5mm leaf springs

Hotswap or Solderable PCB with In-Switch RGB LED

PCB compatible with QMK firmware, configurable by VIA configurator

PCB/plate mounting hardware for stable hotswap performance.

Contents:

1 x Top Enclosure (HHKB or FULL, Aluminium)

1 x Base Enclosure (Aluminium)

1 x Plate (BEAM, Polished Aluminium)

8 x RW Black M3x12 T10 Fixtures

8 x RW Black M2x4 T10 Fixtures

6 x RW Black M2x3 T10 Fixtures

6 x RW Black M2x3 CSK T6 Fixtures

6 x RW Black M2x3.5 Spacer

1 x wilba.tech WT60-B or WT60-Bx PCB

1 x XO Switchpuller

1 x RW T10 Torx Tool

1 x RW T6 Torx Tool

1 x Black Metal End USB-C to USB-A cable (USB 3.0) (Braided) - 1.5M

1 x Set of Poron/Foam Pads

1 x Instruction Booklet

1 x Various Packaging

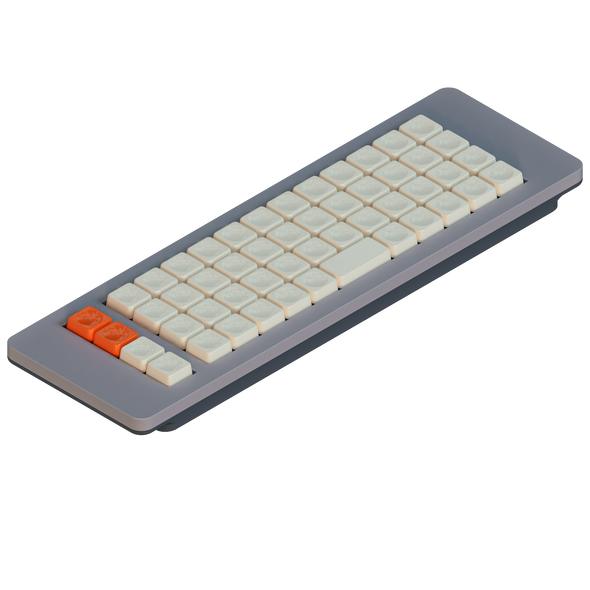

Layouts: