As we wait for products to arrive at our warehouse, we have been working on some items which will be included with our upcoming releases:

Microfiber Gloves:

Cleaning Cloths:

And some new products:

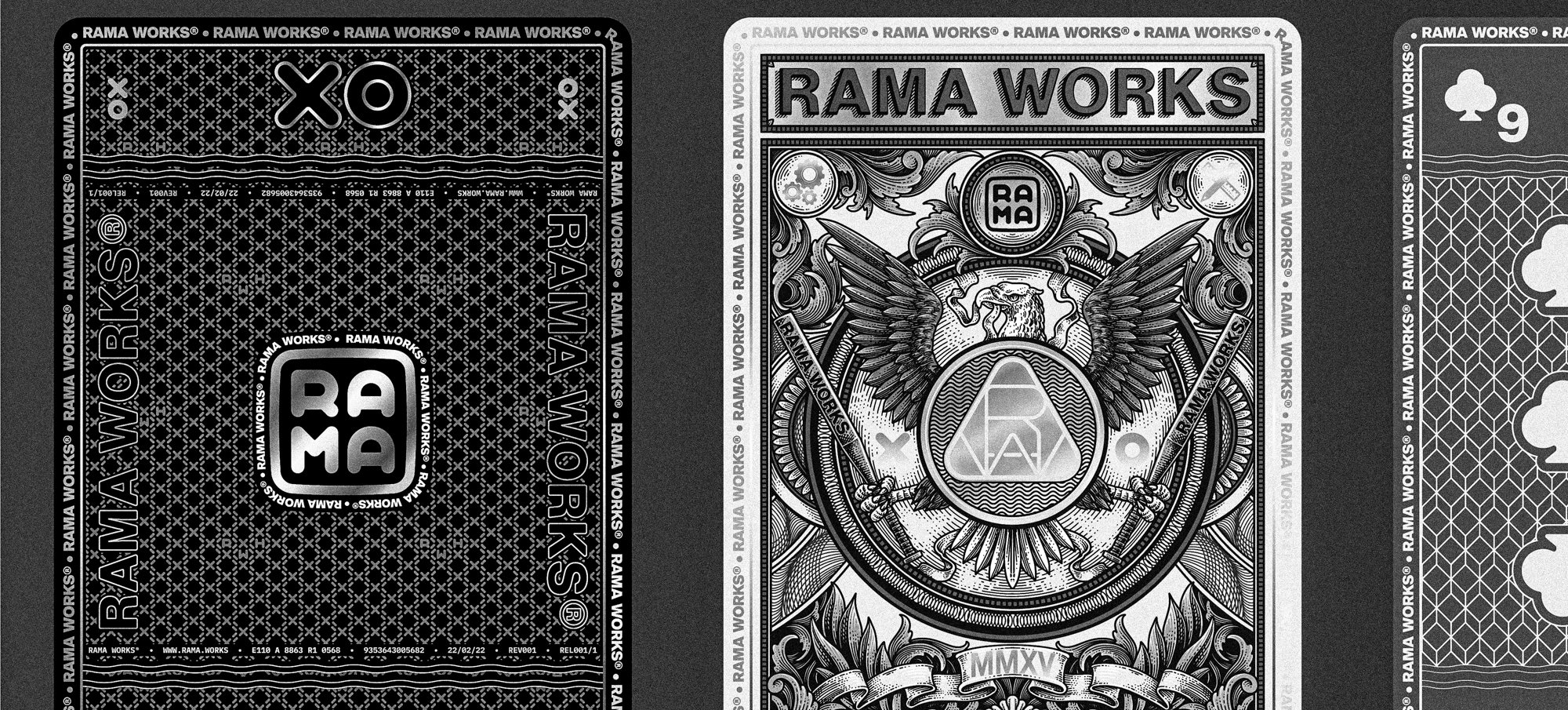

Playing Cards

WORK IN PROGRESS. Featuring holographic, foil and other premium features.

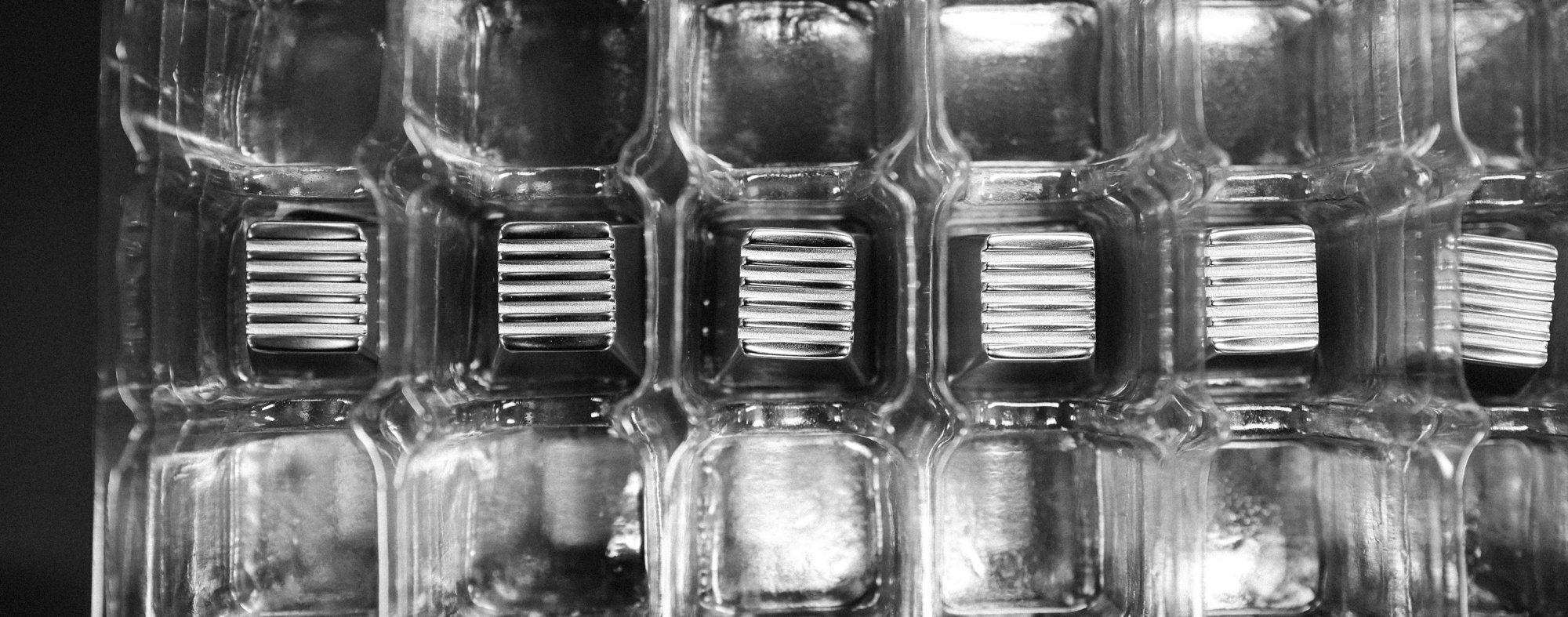

NFC Access Control Cards:

We needed some elite access control cards for our office, so we decided to make our own! They’re stainless steel, weighing in at 25g and 0.8mm thick. There’s a deep-etched circular center on one side where the RFID chip sits, allowing us to not use the typical plastic lamination for one side of the card and have it remain full metal. They are laser etched, painted and have a lot of detail. These will first be available in stock alongside some of the other items arriving next month: The XO Team cap, XO Pens.

Collaboration Artisan Keycaps:

We’ve received another batch of our collaboration caps which are currently being QC'd and packed by our warehousing team as quickly as possible to our distributors. For those who have purchased directly from us, please contact us through support@rama.works if you have moved/changed addresses and our team will be happy to assist as best we can.

XO Pens

After initial QC we have opted to refinish the brass units of the XO PENS. We are expecting them to arrive by the end of this month leading up to the start of next month.

UPDATE: The first batch is inbound to our warehouse (the brass ones are being re-finished as we weren’t satisfied with the finish of the brass units)

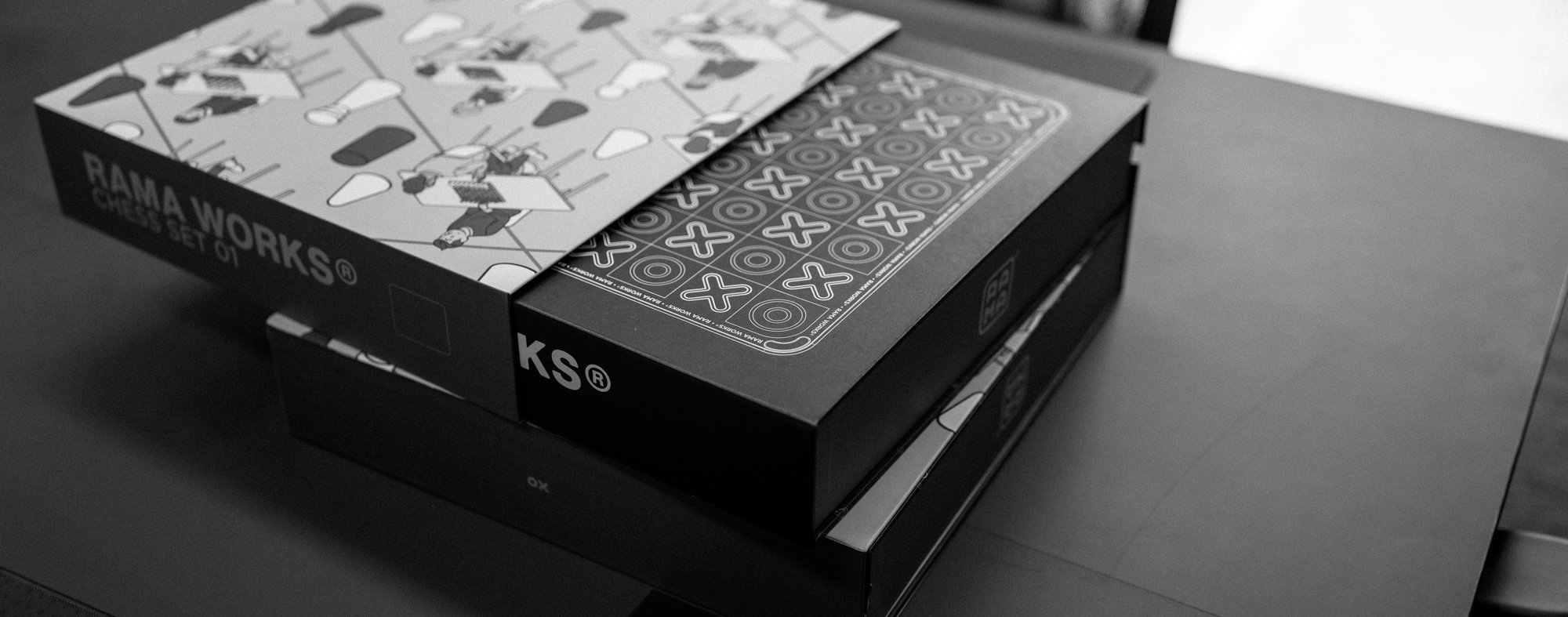

Chess Set:

The first revision of the packaging came in which we are really happy with. It feels like a solid showcase piece you would want to keep on a coffee table. There have been some minor adjustments made and the second set of samples are en route.

JARS:

We were expecting to receive the JARS last week, but the manufacturer has informed us of an issue with the rubber seals. The new gasket tooling will be finished by next week and the JARS will ship out that same week. We will post updates when this has been shipped through our socials e.g. Instagram, so please be sure to follow us if you haven’t already.

UPDATE: These are inbound to our warehouse.

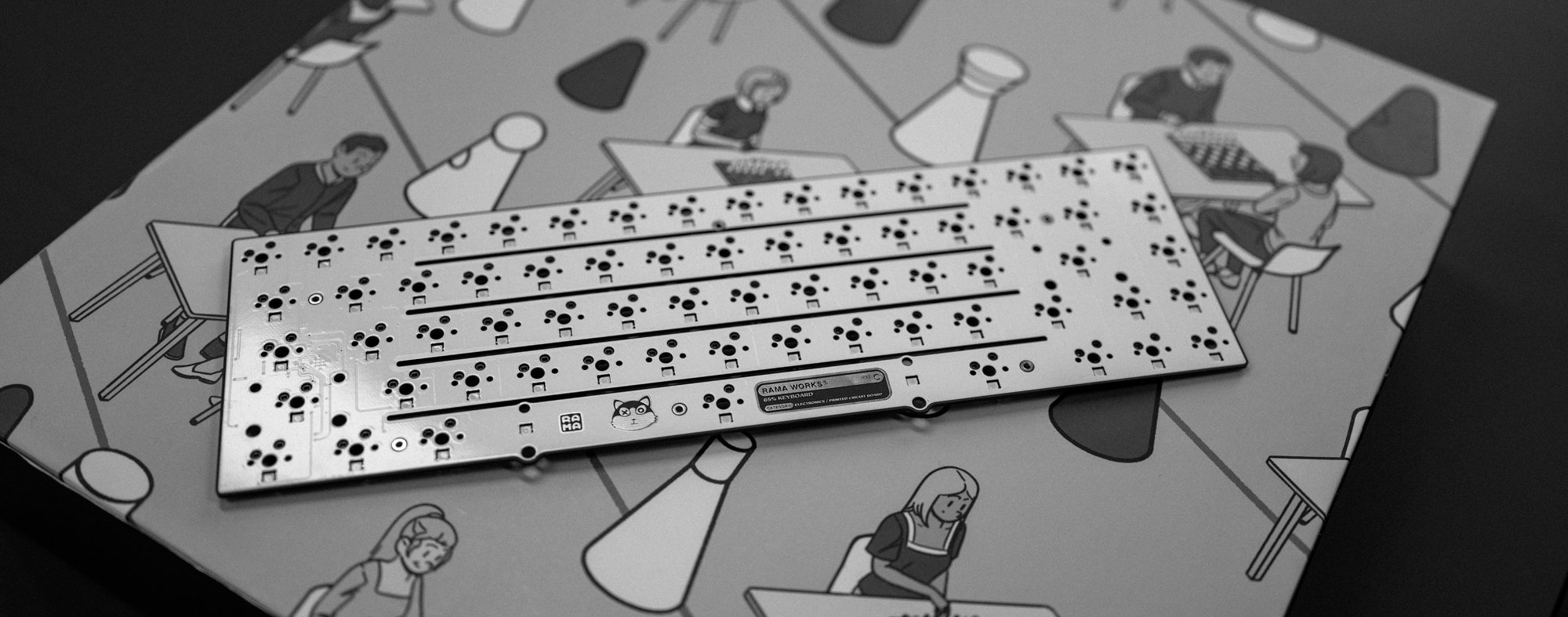

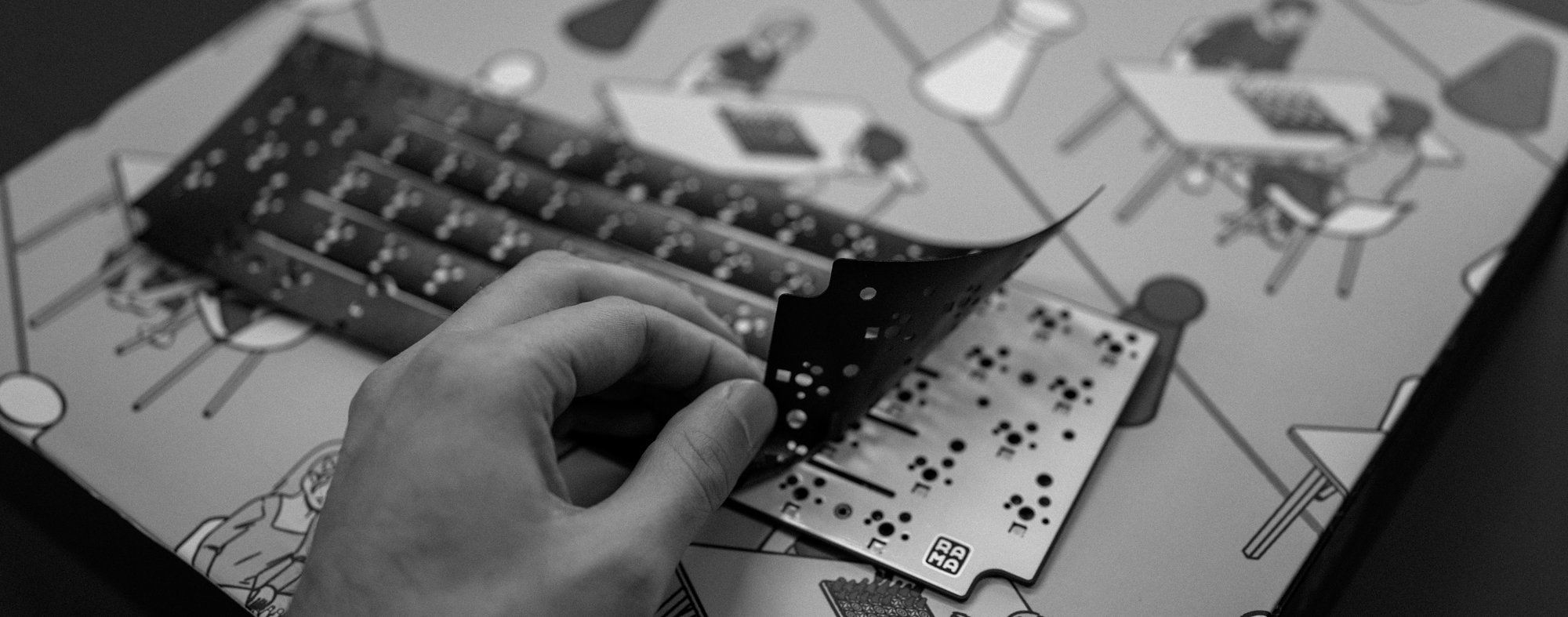

60%/65% PCB's:

The latest round of PCBs have arrived and we are currently performing further evaluation and testing. We are also remoulding the PE Foam to adjust the sound signature and adding additional cutouts for the stabilisers.

THERMAL

The SEQ 2 THERMAL units are in the final stages of assembly and packaging at the factory and will soon move to complete the assembly/packing of the THERMAL+ units. We will create another update when these are done and ready for sea-freight.

M60-B, M65-C, U80-B:

At this stage we’re looking at next year for fulfillment, we will keep updated if this is pushed forward.

KARA:

Pending the completion of the updated PCB’s we expect we can have the units completed soon after.

MATS: (IN PRODUCTION)

Packaging production is underway and when complete, will be assembled and shipped to our warehouse for fulfillment. We are expecting these to arrive in 2 months.

LOVE MATS DONATION:

Proceeds of our LOVE Mat edition MATS will be donated to Beyond Blue. Every month, thousands of people reach out to Beyond Blue for advice, support and information. Your donations go directly towards funding Beyond Blue’s Support Service so these calls don’t go unanswered. By supporting Beyond Blue, we are joining a community that is working to reduce the stigma, prejudice and discrimination that act as barriers to people reaching out for support.

Doubleshot Keycaps (KATE/CAPS):

The latest round of fine tuned samples have arrived and there are still very minor inconsistencies. We were still not 100% happy with the quality and again, Injection Molding is an iterative process - tooling after tooling changes until the end result is what’s expected. We are expecting to receive another batch soon, and will post pictures when they’re in.

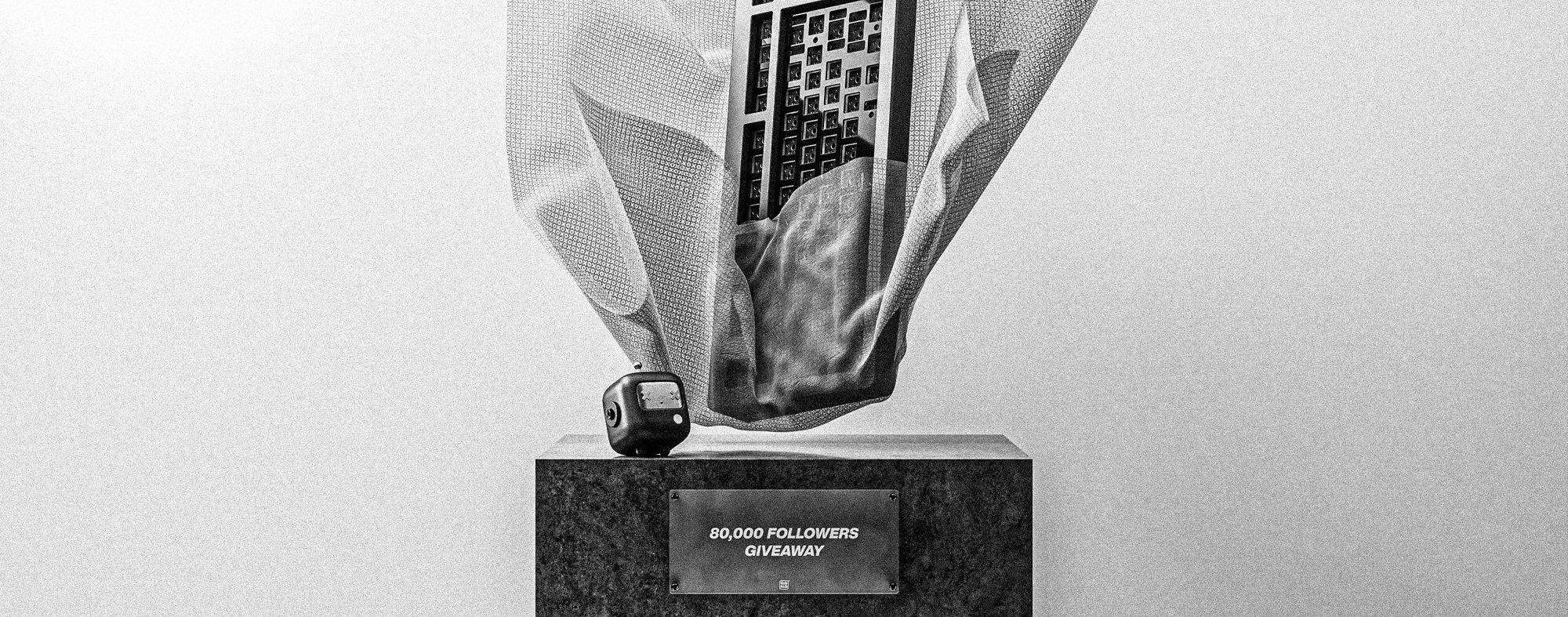

INSTAGRAM 80K GIVEAWAY

We’ll be soon announcing a giveaway for reaching 80K followers, with a few exciting prizes!